Blog

The most common embroidery mistakes and how to avoid them

The most common embroidery mistakes and how to avoid them

The embroidery process involves intricate needlework, often susceptible to errors. Common faults include misaligned stitches, color mismatches, and fabric puckering. These can result from machine malfunctions or human oversight. Attention to detail and quality control are critical in minimizing these issues to maintain high-quality embroidery standards.

Thread Breakage

Source: www.ageberry.com

Thread breakage is a common fault in embroidery that occurs when the thread snaps or frays during the stitching process. This can be caused by various factors, such as incorrect tension settings, inadequate threading, or using old or low-quality thread.

To prevent thread breakage, ensure the thread is properly threaded and the tension is set correctly. Change the needle frequently to maintain sharpness and avoid using worn-out or weak thread. Testing the embroidery design beforehand can also reveal any potential issues.

Uneven Stitching

Source: seampedia.com

Uneven stitching is a common embroidery issue that results in uneven or jagged lines, inconsistent stitch lengths, or uneven fill areas. This can be caused by various factors, such as incorrect tension settings, using the wrong needle, or unlevel fabric. To prevent uneven stitching, ensure the correct needle and thread weight are used for the fabric, check the hoop and fabric are flat and even, and adjust the tension settings where needed. Testing the design on scrap fabric can also reveal any potential issues before stitching on the final project.

Puckering

Source: cheapdigitizing.com

Puckering occurs when the fabric bunches or wrinkles around embroidery designs, creating an unappealing look. This issue can be caused by several factors, such as improper stabilizer use, incorrect tension settings, or using a needle that’s too large.

To prevent puckering, use the correct stabilizer type and weight for the fabric, ensure the tension settings are correctly adjusted, and use a smaller needle size. Additionally, testing the design on scrap fabric before stitching on the final project can reveal any potential issues.

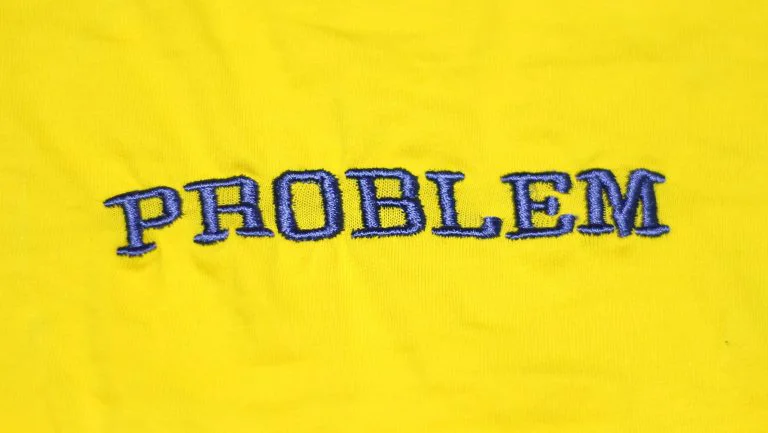

Needle Breakage

Source: www.ageberry.com

Needle breakage is a common issue in embroidery projects and can occur for various reasons, such as using a bent or dull needle, incorrect threading, or a wrong needle type for the fabric.

To prevent needle breakage, use a new and correctly sized needle appropriate for the fabric type. Ensure that the needle is correctly threaded and that there are no obstructions in the machine’s bobbin or feed dog. It is also important to avoid pulling the fabric during stitching and to adjust the machine’s speed to prevent excessive strain on the needle.

Design Distortion

Source: www.toughkittencrafts.com

Design distortion can occur in embroidery projects, resulting in an inaccurate and distorted final product. Causes of design distortion can include using an incorrect digitized design, incorrect hooping, improper tension, or using a wrong needle type.

To prevent design distortion, ensure that the digitized design is appropriate for the fabric and stitches chosen. Properly hoop the fabric and ensure the tension is correctly adjusted. It is also important to use the correct needle type for the fabric and to avoid excessive pulling on the fabric during stitching.

Bird Nesting

Source: www.machineembroiderygeek.com

Bird nesting is a common issue in embroidery, where unwanted thread clumps form at the back of the fabric. This can be caused by a variety of factors, including incorrect tension, thread breakage, an improperly threaded machine, or using an incorrect needle type.

To prevent bird nesting, ensure the machine is properly threaded and the tension is adjusted correctly. Use high-quality thread and select the appropriate needle type for the fabric. Regularly clean the machine and change the needle regularly to avoid thread breakage. Practice different sewing techniques to prevent excessive force on the thread.

Fading Colors

Source: www.cre8iveskill.com

Fading colors in embroidery can be caused by several factors, such as exposure to sunlight or heat, over-washing, using bleach, or submerging in water. To prevent color fading, store finished pieces away from direct sunlight and heat. Wash the fabric gently in cold water, and avoid using bleach or harsh detergents. Consider using fabric dye designed for embroidery to restore color.

To prevent embroidery faults, it is critical to use high-quality materials, including fabrics, threads, and needles. Store embroidery pieces away from direct sunlight and other environmental factors that can cause fading or discoloration. Gentle washing and avoiding harsh detergents are also essential to maintaining vibrant colors. It is also recommended to take preventive measures like knotting the threads before starting embroidery and regularly cleaning the machine to avoid any malfunctions. Following these measures will help in avoiding embroidery faults and enhancing the longevity of the embroidery work.